Electrical gremlins can be a major headache for pickup truck owners. From dim lights to a dead battery, electrical issues create frustration and downtime. That’s why having a basic understanding of the diagnostic process is valuable, whether you’re a seasoned gearhead or just someone who likes to be informed about their vehicle.

The Toolkit: Beyond the Basics

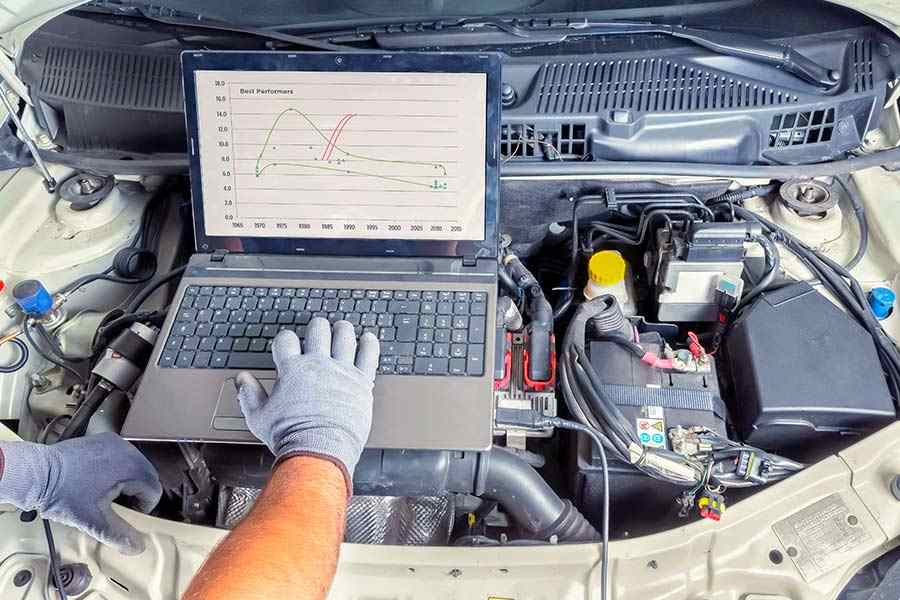

While anyone can check a blown fuse, deeper electrical diagnosis requires specific tools:

- Multimeter: The cornerstone of electrical checks. Measures voltage, current, and resistance, revealing vital details about the state of a circuit.

- Scan Tool/Code Reader: Connects to your truck’s onboard computer (OBD-II). This translates fault codes from the computer into understandable issues, guiding your diagnosis.

- Wiring Diagrams: Think of these as treasure maps of your truck’s electrical system. Having model-specific diagrams is essential for tracing problems accurately.

The Diagnostic Methodology

Professional mechanics and experienced DIYers follow a systematic process:

- Gather Information: Start with the obvious. What’s the exact problem? Does it happen all the time, or only under certain conditions? This context is key.

- Visual Inspection: Simple as it sounds, look for anything damaged, corroded, or loose. Burnt wires or melted connectors could be the smoking gun.

- Check the Basics: Before going deeper, verify battery health and ground connections. A weak battery or bad ground can mimic more complex faults.

- Isolate the Circuit: Use wiring diagrams to understand the components involved. Is it a headlight issue, power window problem, etc.? This narrows the search field.

- Utilizing the Multimeter:

- Voltage Tests: Check for power where it should Low voltage indicates a supply issue or excessive resistance.

- Resistance/Continuity Checks: Tests integrity of wires and components. “Open” circuits or high resistance pinpoint damaged areas.

- Component Testing: Individual components might need specific tests. Sensors, relays, and switches often have a manufacturer-specified testing procedure for accurate diagnosis.

Related: Diagnosing and Fixing Engine Misfires

Heavy-Duty Considerations

Heavy-duty pickups often have complex electrical systems due to their auxiliary equipment:

- Trailer Wiring: Trailer light issues are common culprits. Corrosion in connectors, poor grounding, or broken wires requires thorough inspection.

- Aftermarket Accessories: Poorly installed accessories can create a host of problems, from parasitic battery drain to interference with other systems.

- Upfitter Equipment: Dump bodies, plows, etc., have their own control systems. These can interact unexpectedly with the truck’s factory wiring.

When Calling in the Pros

Some issues go beyond DIY capabilities:

- Intermittent Faults: These are the toughest to find. They may require specialized tools or a technician’s experienced intuition.

- Computer-Related Issues: Modern trucks are rolling computers. Reprogramming or complex computer module diagnosis may need dealership-level equipment.

Key Takeaways

- Patience and Methodical Approach: Electrical diagnosis is often detective work. Don’t rush—a methodical approach will save time in the long run.

- Safety First: Always disconnect the battery before working on major electrical components.

- Know Your Limits: No shame in seeking professional help for complex problems. It can ultimately save money and prevent further damage.

Understanding the diagnostic process is an investment. You’ll be better equipped to troubleshoot minor issues, and a more informed customer if it comes time to visit a mechanic.